HS disc magnetic separator (disc mine tail sorting machine)

The disc tailings recovery consists of five main parts: main engine, mine-deficient device, collecting tank, chute and rack. The working principle is that the host disk is installed in the chute, the slurry flows from one end of the chute, and through the gap between the disk and the disk, the magnetic mineral in the slurry is adsorbed on the surface of the disk, and the mineral slurry of the non-magnetic mineral remains from the other end of the chute. . The main disk rotates, and the magnetic mineral adsorbed on the surface of the disk is taken out of the slurry surface. When entering the unloading area, the magnetic mineral adsorbed on the magnetic surface is thrown into the collecting tank by the unloading device inserted between the gaps of the disk and rotating. The output is collected by the collecting tank.

Advantages of disc tailings recovery machine

1. Magnetic field arrangement: The magnetic pole spacing of the magnetic disk is small, and there is no zero magnetic area between the magnetic disk and the magnetic disk.

2, unloading: unloading is non-contact type forced unloading, leaving a layer of powder protective layer on the surface of the disk, the surface of the disk is not worn, the life of the whole machine is 8-10 times of the conventional type, and it also makes the grade of recycled magnetic mineral improve.

3. Large processing capacity: The machine is specially designed for re-election of tailings. Its structure has the characteristics of dealing with large flow and low-grade tailings. It is several times or even dozens of times of the processing capacity of the existing tubular magnetic machine.

4, high recovery rate: all materials passing through the disk are affected by the magnetic field, the minerals are fully recovered, and the recovery rate is high.

5. Water saving: Due to the unique field arrangement, the magnetic mineral contains a large amount of water in the stomach, and the removed minerals are in a flowing state, basically with or without adding water or adding a small amount of supplementary water.

6. Section: The recovery of a disc-type tailings is several times or even ten times that of other ordinary equipment. The installed capacity is only a few kilowatts, so the power saving effect is obvious.

7. Convenient installation: The disc tailings recovery machine has large processing capacity, small footprint, small difference between feeding and discharging, and can be installed basically in the place with tail chute.

8. High economic efficiency: equipment investment is small, output efficiency is high, and annual output efficiency is generally several times or even ten times of equipment investment.

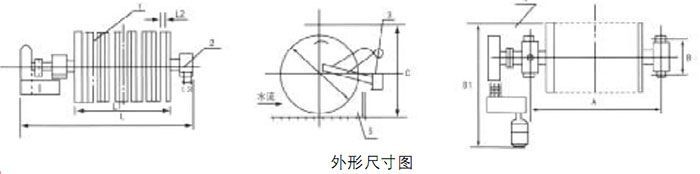

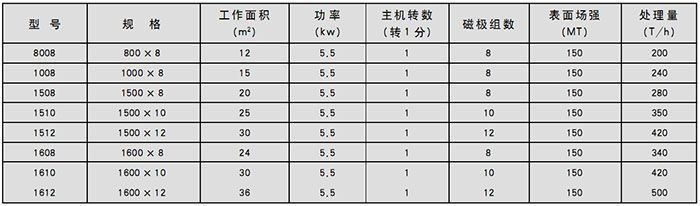

Dimensions